This machine is more suitable for recycle plastic processing. Since the machine has a large extrusion force, it can be processed at low temperature, so the influence of the waste material performance will be reduced.

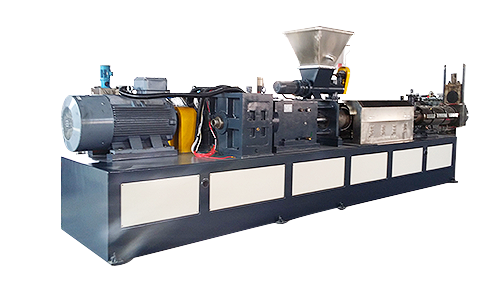

I Waste foam plastics granulator

The waste foam plastic has the characteristics of large volume, small density and large compression ratio. At present, single screw is used for processing the waste foam plastic, but it is difficult to feed. The single screw’s compression ratio is limited, with low output, poor plasticizing performance and high energy consumption so that requires large screw diameter. Using parallel twin screws extruder, the feeding of which is also difficult with small output. Meantime, using conical counter-rotating twin screws extruder has good convenient of feeding though, plasticization and mixing effect is poor. While the conical co-rotating twin screws extruder inherits the advantages of parallel twin screws extruder and conical counter-rotating twin screws extruder, the diameter of the feed section is large and convenient for feeding, and it also has the advantages of good plasticization, uniform mixing, large cylinder pressure and small energy consumption.

II Waste woven bags granulator

The waste woven bags have the characteristics of large volume, loose material and large compression ratio. At present, single screw extruder is used in the market for processing, with low output and difficult feeding however. The conical co-rotating twin screws extruder has the advantages of large diameter of feed section, convenient feeding and large compression ratio, thus ensuring the plasticization to increase the output and reduce the energy consumption.

III Waste film granulator

Compared with the waste woven bags, the waste film has the characteristics of looser material, smaller packing density and greater compression ratio. At present, single screw processing is used in the market. It also has the disadvantages of large energy consumption and low output, with difficult feeding. The conical co-rotating twin screws extruder has large diameter of feed section, convenient feeding and large compression ratio, thus ensuring the plasticization to increase the output and reduce energy consumption.

IV Waste EVA granulator

The processing of waste EVA has the characteristics of high temperature, large shearing force and high plasticization. The single screw extruder has little shear force and poor plasticization. While using conical co-rotating twin screws extruder, it has strong shearing force, high compression ratio, good plasticizing and even mixing.

| Name | Content | Name | Content |

| Screw diameter(mm) | 75/150 | Main motor(kw) | 110 |

| Screw valid length(mm) | 3600 | Main motor driving mode | Frequency control |

| Max production capacity Output (Kg/h) | 560 | Application scale | Classified, cleaned, pulverized and dry waste plastic |