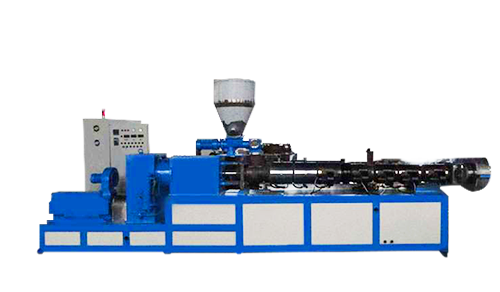

“Conical co-rotating twin-screw filling master batch granulator”is the well-designed in order to granulate the master batch. It is the new generation of environmentally friendly granulation equipment . This machine is suitable for material modified granulation, such as 18% of PE/PP(base material),78% of TSP, and 4% of others. The product not only has the advantages of energy-saving, high yield, good plasticization (high pressure plasticization),high mixing,slight noise, and long screw service life, but also has the features of quick cleaning in color change,labor intensity reduction,and environmental pollution decrease. According to the actual test and customer feedback, the product can save more than 30% energy compared with similar products and double increase of yield. It is the ideal modified plastics granulation equipment at present.

Model 65 “conical co-rotating twin-screw fill master batch granulator” has characteristics in high-pressure and good plasticization , thus owning good mixing and plasticizing effect, and perfect quality in finished products. During production,the power consumption of the host can save more than 60 kwh per ton. Taking 10 tons per day as an example, we can see over 600kwh electricity can be saved one year(360 days), thus the cost of machine can be balanced through saving in electricity bill in 2 years.

| Name | Content | Name | Content |

| Screw diameter(mm) | 65/130 | Main motor(kw) | 90 |

| Screw valid length(mm) | 3150 | Main motor driving mode | Frequency control |

| Max production capacity(Kg/h) | 620 | Application scale | PE high-calcium granulation(Content of calcium carbonate about 80 percent) |