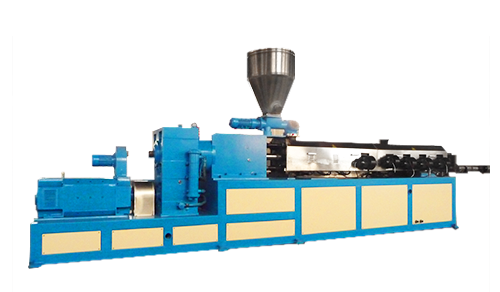

conical co-rotating twin screw extrusion, which have both advantage of big extrusion pressure of conical counter-rotating twin screw extruder and good plasticization of parallel co-rotating twin screw extruder, in addition, it has stable extrusion pressure of single screw extruder, saving energy obviously, and will become the best equipment to make aluminum composite panel.

At present, the aluminum composite panel is usually extruded by single screw, with main motor power 160-250KW, output around 600-700KG/hour, however, its host engine consume power is more than 300 kwh per ton. Compared to single screw extruder, conical co-rotating twin-screw extruder has obvious advantage of:

I Saving energy: the SJSZ-85 extruder is able to save 150 kwh per ton, 2000-3000 kwh in total every day, so could return the investment soon;

II High output: single screw extruder production for 1200-1300 plates per day, the output of SJSZ- 85 twin screw extruder can reach to two or four times of it per day;

III Good plasticzation: it is able to process not only for A grade, but also for C grade recycled plastic, so it can use higher proportion of recycled plastic or filler than single screw extruder, saving much cost of raw material. It is suitable for high fire retardant ACP production;

IV The machine uses large rotating bearing and large taper screw, so that could bear high torque extruder;

| Description | 75 |

| Processing range | Aluminum plastic sheet shed material ,return material and high Calcium fireproof material |

| Dia of screw(mm) | 75/186 |

| Effective length of screw(mm) | 3800 |

| Screw rotating speed(r/min) | 6-72 |

| Screw barrel material | 38CrMoAlA |

| Main motor power(kw) | 160/4 |

| Main motor drive mode | Frequency control |

| Heater material | Electromagnetic and cast aluminium heater |

| Output(Kg/h) | 1100 |

| Typical customers | SHANGHAI JIXIANG TECHNOLOGY GROUP |